This is how jewelry casting companies work smarter with PIRO Fusion

Jewelry casting and rapid prototyping companies are operating in a very specific way within the jewelry industry, thus, their business management solution should be specific too.

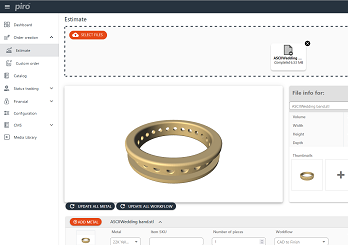

Providing price quotes, accepting orders (CAD files in most cases), managing production, meeting deadlines, and informing the customers are the main pillars of such businesses. What if they could be automated?

PIRO Fusion has all the tools to achieve this. First and foremost, it was developed to serve the production automation needs of a jewelry casting company. A decade’s worth of experience in the field helped us create specific tools and production workflows for casting companies and for end-to-end jewelry manufacturers. Today, and we are stating this with confidence, PIRO Fusion can solve all major management problems that companies are facing. What are these problems exactly?

- Price quotes are time-consuming and require much back and forth with clients

- Getting design approvals from customers is difficult

- Inventory is handled manually and it’s not connected to the production

- Reordering raw materials is a never-ending hassle

- Metal losses are not handled transparently

- Tracking job orders and order statuses are difficult, deadlines are often missed

- Human errors appear too often during production

- Invoicing and shipping requires a full-time job

- Nobody knows exactly who is working on a particular order and how much time was spent on the individual orders

Automation has brought real benefits to PIRO Fusion users

Many of the long-time PIRO Fusion users were able to grow their business and retain more customers simply because business automation helped them to improve their customer service. Numbers don’t lie, their growth and improvement are both real.

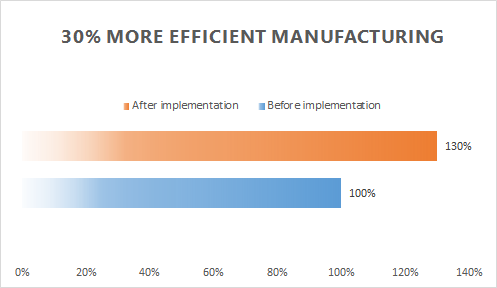

30% more efficient manufacturing:

PIRO users were able to process more orders with the same number of staff. This is a clear indicator of how process optimization and better management can improve a jewelry business.

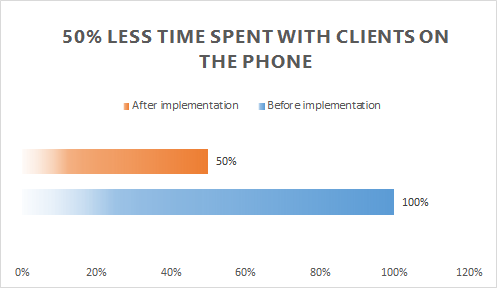

50% fewer calls from the clients:

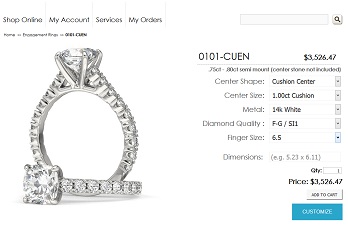

Customers can request quotes and submit custom orders using the PIRO Customer Portal.

Also, they can get real-time information about their orders, and this is just the tip of the iceberg. The Portal can offer much more automation (see below).

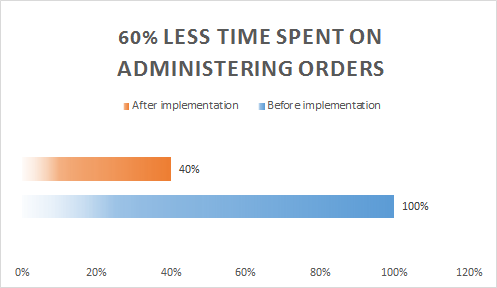

60% less time spent on administering orders:

PIRO users were able to drastically reduce the time spent on production management. When all details are tracked by PIRO, the production manager can sit back and focus on more important tasks like quality assurance.

Overall, this leads to better customer satisfaction.

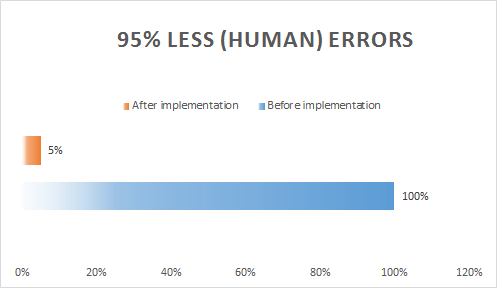

95% less (human) errors:

It's easy to do mistakes when things are unorganized and untraceable or when processes are too manual. Prior to implementing PIRO, our clients suffered of errors due to poor communication.

With PIRO, they were able to automate repetitive tasks (e.g. invoicing) and set up warnings to avoid possible errors. No more miss-typed data, missed deadlines or unclear instructions.

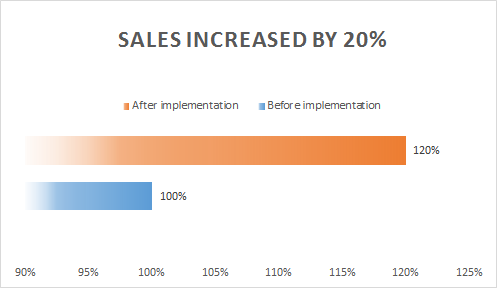

20% increased sales:

Our experience is that casting companies can grow their business in two different ways. On the one hand, by working more efficiently more orders can be accepted and shipping can be done faster. On the other hand, professional service (i.e. fewer missed deadlines, online platform to submit orders, seamless communication) leads to better customer retention. Satisfied clients will come back and deal with you again. Remember: it costs less to work with the same client repeatedly than hunting for new ones all the time.

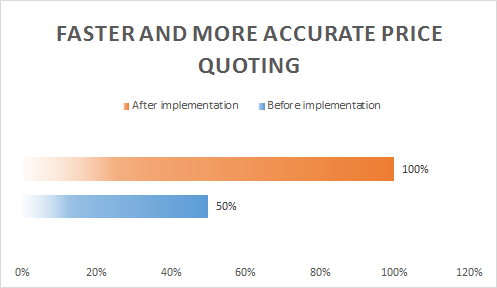

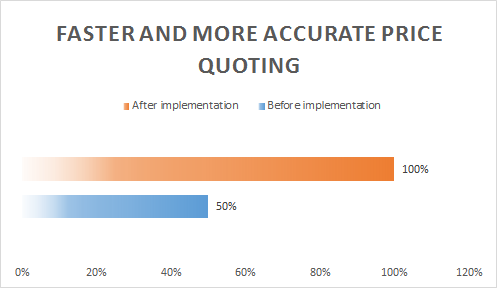

100% more accurate quoting and costing:

Casting companies we work with are really good at one thing: they provide price quotes much faster than their competitors. With PIRO they can use automated pricing formulas and track live metal market prices too. They are getting quotation requests through the online Customer Portal, and not through emails or calls. In most cases, quotations are ready within minutes and clients can approve or decline them easily through the Customer Portal.

100% visibility over job orders:

Usually, casting companies are dealing with a high volume of orders on a daily basis, thus transparency between these orders is a key element of everyday operations.

PIRO clients literally track every detail about their orders: workflows, job statuses, user assignments, deadlines, issued weights, metal losses and the list could go on.

Jewelry casting and service companies using PIRO

"Prior to purchasing and implementing PIRO, for years we ran an entirely manual process for tracking jewelry production. We are now able to process more manufacturing jobs and complete more orders faster and on-time. We also are able to track and analyze more accurate data to make better company decisions. This has helped to increase our client base, and improve customer retention."

"We have been using this jewelry software for 4 years now, and it has transformed our business. Information is critical to the success of any business, and having the details of every job easily accessible certainly makes the running of our business that much easier. All production aspects of our business are handled within PIRO, in particular, the progress of jobs through the factory and their invoicing."

"We were looking for the right jewelry manufacturing software for many years. PIRO is currently used to manage all our business processes and invoicing steps. We estimate that production errors have been reduced by at least 30% since the adoption of PIRO, and the overall savings and increases in production capacity have allowed us to add more staff and increase production. We are grateful to the PIRO team for their professional service."

"PIRO has helped us manage our business more efficiently, reduce the number of production errors dramatically, keep better track of company and customer inventories, and improve our production process by alerting us to bottlenecks and signaling where we were losing significant amounts of time and money. PIRO also connects directly to our website through use of its Customer Portal."

"I can honestly say the PIRO support team has always offered me prompt and reliable customer service. Their team members are always available whenever we need assistance and respond to us in a timely manner. To me, this is one of the most important factors in selecting a software provider. We manufacture jewelry and need to feel confident that we can always rely on our software company."

"In short, PIRO has helped us present a more professional service to our clients by eliminating errors and providing clear and concise information about their jobs' progress through our system. It also enables us to easily recall job information, once again eliminating confusion and enabling simple reordering. Critically, PIRO has also saved us money by vastly reducing overheads, labour costs and errors."

"PIRO connects directly to our website through its Customer Portal, allowing customers to check on the status of their job orders on their own, and to QuickBooks, reducing the amount of time spent on data entry and giving us the ability to manage our business from one place. The support team listens to all of our concerns and has always made an effort to accommodate our needs."

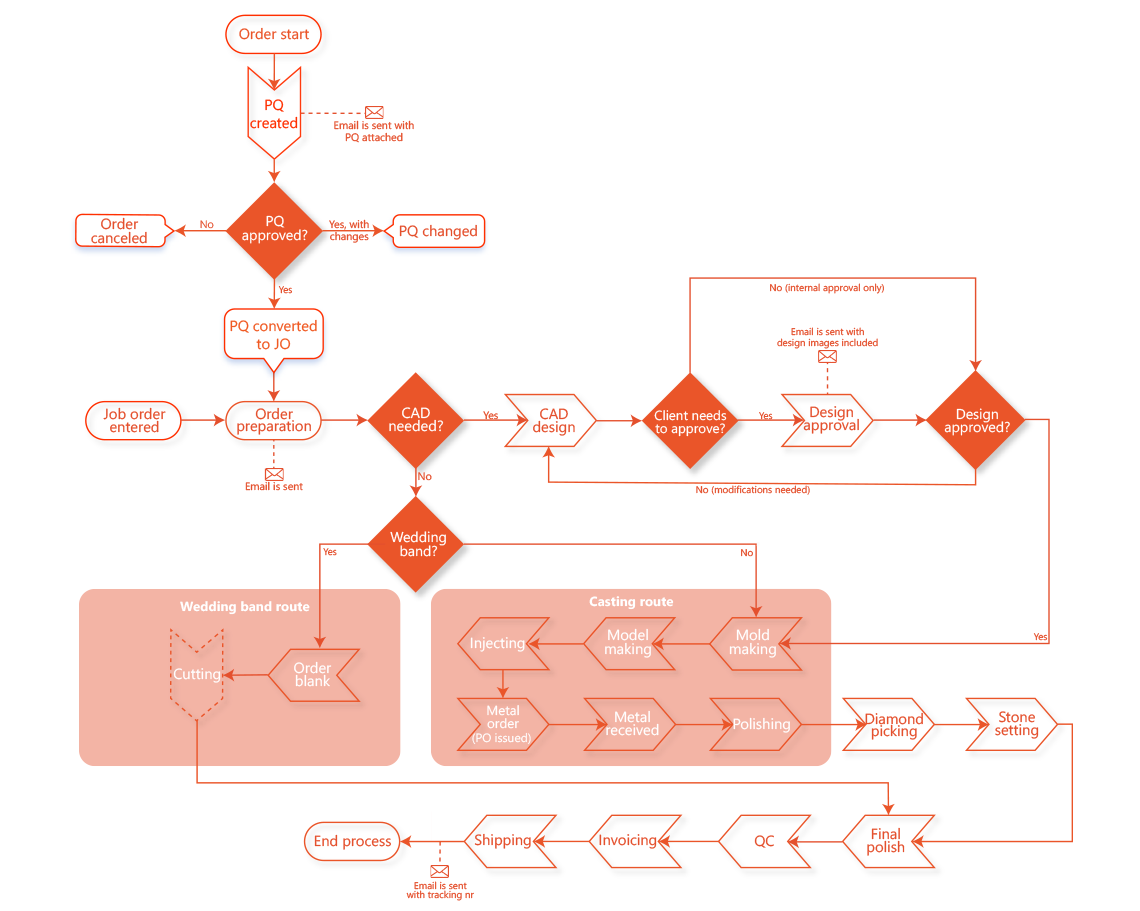

We can set up and automate virtually any business workflow (example)

When we implement PIRO Fusion, we don't ask you to change your processes, we just automate the existing ones. PIRO's flexible workflow configuration allows all production steps to be automated. As a result, you will be able to perform job splits, do actions based on conditions, send auto-emails/notifications, and require the users to enter certain information before routing a job to the next step (e.g .stl file upload, entering item weight, etc.).

Frequently Asked Questions

The system may come with pre-set workflows, but it is not mandatory to use them. It’s easy to create new ones or modify the existing ones. The bottom line is that we always tailor the workflows to the company which implements PIRO.

Yes, you can add multiple job orders to the same casting tree. Moreover, PIRO Fusion can automatically assign jobs to casting trees based on the metals that the job is cast in; this helps prevent casting errors as your users can only cast jobs from the correct metal.

During the casting process, users can track all weight movements. First, PIRO Fusion can calculate the weight of the needed metal based on the wax tree (you can use an integrated scale for this). Then it also tracks the issued weight, the returned finished good weights (even on item level) and other returned weights (scrap, fillings, etc.). Based on these numbers, PIRO Fusion calculates the metal lost during casting and it will warn you if the loss percentage is higher than previously anticipated.

No, you don’t have to manually adjust the inventory when you remove items from your safe. It’s all automatic as the production and inventory modules in PIRO Fusion are interconnected. Whenever you work on a job order, the system will remove the right amount of metal, stone or diamond from the inventory. It’s that simple.

Yes, PIRO Fusion can track your minimum/maximum inventory levels and can create Purchase Orders whenever you are running low on a material. Also, you will be able to calculate your needs based on the current job orders, thus you can keep your inventory at a minimum and order materials only if you have an order placed.

Yes, PIRO Fusion supports FedEx, USPS, ParcelPro and it can calculate the shipping rates. Moreover, you will be able to generate shipping labels from PIRO Fusion, and pull the tracking numbers from the shipping provider’s site.

PIRO Fusion allows you to assign jobs to users and measure their performance (speed and quality). For the users, there is a Timekeeping app where they can manage the orders and the activities they are they working on.

Although PIRO Fusion can handle invoices, customer credits and payments, we use QuickBooks for accounting purposes. QuickBooks Bridge is an add-on to PIRO Fusion and you can automate the mapping with it: all invoices, credit memos and new clients can be mapped over to QuickBooks in real-time.

There is no limitation on how many of your clients can use the Customer Portal. You are able to give access to all of them or only to selected ones. The only limitation is related to orders. By default, 500 orders can be accepted through the Customer Portal per month. Our representatives will provide more information about this when a PIRO proposal is being submitted to you.

Most of the casting companies we work with are using barcode scanners to move job orders, digital scales to read weights and printers to print out job bags. If you wish to run PIRO in-house, a server would also be required (or you can host it on our servers). We can provide these pieces of hardware if needed, but you can easily buy them yourself from Amazon or similar sites based on the specifications provided by us.

How to use Zoho Meetings?

We use the Zoho Meetings platform for online meetings and appointments. Once the appointment is set, we will e-mail you the meeting link. Zoho Meeting is a simple platform, but if you need help, you can get instructions on how to use it: How to Join as an Attendee on Zoho Meeting.

Request a walkthrough

Contact us

MindSpark LLC

630 Fifth Avenue, Suite 2000

New York City, NY, 10111

Tel: (888) 245-1563 #1

Email: sales@gopiro.com